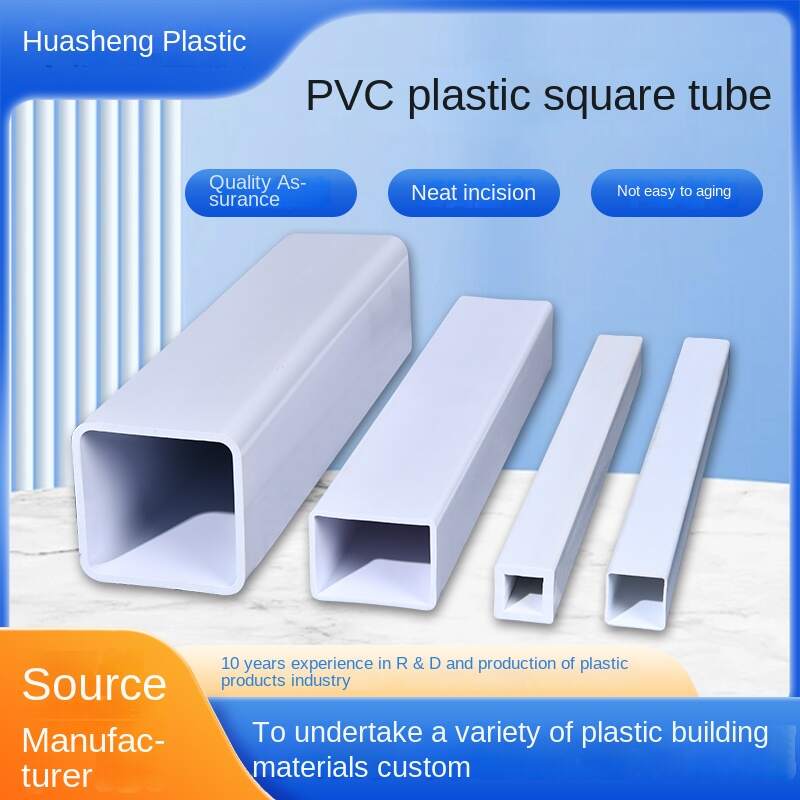

PVC transparent square pipes are an excellent choice for a variety of applications, including electrical conduits, decorative elements, and plumbing systems. As a leading manufacturer in the industry, HSZ offers high-quality PVC square pipes that are durable, easy to work with, and highly versatile. In this article, we will guide you through the process of cutting and installing PVC transparent square pipes, ensuring a seamless and professional installation every time.We have every reason to believe. plastic corner guard It will become the mainstream of the industry and will gradually affect more and more people. https://huashengzheng.com/

What You Need to Cut and Install PVC Transparent Square Pipes

Before you start cutting and installing your PVC square pipes, make sure you have the following tools and materials:

PVC Transparent Square Pipes (from HSZ)

PVC Pipe Cutter or Hacksaw

Measuring Tape or Ruler

Marker or Pencil

Deburring Tool

PVC Pipe Glue or Adhesive

PVC Fittings (for connections)

Gloves and Safety Glasses

PVC transparent square pipe

Step 1: Measure and Mark the Pipe

The first step in cutting your PVC transparent square pipe is measuring the length needed for your project. Use a measuring tape or ruler to ensure accurate measurements. Mark the cutting lines clearly with a pencil or marker to help guide your cut. It¨s essential to double-check the measurements before cutting, as cutting is irreversible.

Step 2: Cutting the PVC Pipe

Once you¨ve marked the cutting lines, it¨s time to cut the PVC pipe. You can use either a PVC pipe cutter or a hacksaw for this task. A PVC pipe cutter is highly recommended as it provides a clean, precise cut, while a hacksaw can be used if a pipe cutter is unavailable.

For Pipe Cutters:

Place the pipe in the cutter, aligning it with the cutting blade.

Slowly squeeze the handles until the blade cuts through the pipe. Keep the pipe steady and apply consistent pressure to achieve a smooth cut.

For Hacksaws:

Clamp the pipe firmly in place to prevent movement during cutting.

Use a fine-toothed hacksaw blade for a cleaner cut and saw through the pipe slowly, applying even pressure.

Step 3: Deburr the Edges

After cutting, it¨s important to remove any rough edges or burrs that could interfere with the fitting or adhesive bond. Use a deburring tool or a utility knife to smooth the edges. This will help prevent damage to your fittings and ensure a snug fit when connecting pieces.

Step 4: Prepare for Installation

Now that your PVC pipe is cut to the desired length and the edges are smooth, it¨s time to prepare for installation. If you¨re joining multiple pipes or connecting fittings, make sure the ends of the pipes are clean and dry.

Step 5: Apply PVC Glue or Adhesive

For a strong, permanent connection, apply PVC glue or adhesive to the ends of the pipe and the corresponding fittings. Make sure to use the appropriate adhesive designed specifically for PVC pipes.

Apply the Adhesive:

Coat both the pipe and the fitting with a thin layer of glue.

Insert the pipe into the fitting, giving it a quarter turn to spread the glue evenly.

Allow the Adhesive to Set:

Let the adhesive cure as per the manufacturer¨s instructions, usually for a few minutes to an hour, depending on the type of glue used.

Step 6: Install the PVC Transparent Square Pipe

Once the adhesive is set, you can install your PVC transparent square pipes. Depending on your application, this could involve connecting the pipes to existing systems, mounting them on walls, or using additional fittings. Ensure the pipes are aligned properly and securely fixed in place.

Step 7: Test the Installation

After the installation is complete, it’s essential to test the system for leaks, stability, and alignment. If you¨re installing PVC pipes for electrical conduits, double-check the connections to ensure there¨s no risk of electrical hazards. For plumbing or other systems, make sure there are no leaks and that the pipes are securely fixed.