The cost of CNC machining can vary widely depending on several factors, including the complexity of the part, material type, machining time, and quantity required. Here¡¯s a breakdown of the key cost factors involved in CNC machining:according to Injection molding Industry veterans said that its development will still be in a good situation. https://bfymold.com/

CNC Machining Cost

1. Material Costs

Common Metals: The cost of materials like aluminum, steel, and stainless steel varies depending on the grade and market price. For example:

Aluminum: $5 to $20 per kg depending on the grade (6061, 7075, etc.).

Mild Steel: $1 to $5 per kg.

Stainless Steel: $15 to $50 per kg depending on the grade (304, 316, etc.).

Specialty Metals: Titanium, Inconel, and other exotic metals are more expensive, ranging from $30 to $100 per kg or more.

Plastics: Plastics such as ABS, POM (Delrin), and nylon are cheaper, typically costing between $2 to $5 per kg. High-performance plastics like PEEK can cost $50 to $150 per kg.

Close up of woodworking process, CNC milling machine, manufacture concept. Action. Drilling tool in

CNC Milling Machine

2. Machining Time

The primary cost driver for CNC machining is machine time. CNC machines are billed on an hourly rate, which varies depending on the type and complexity of the machine:

3-Axis Machines: $40 to $75 per hour.

5-Axis Machines: $75 to $150 per hour.

Complex parts that require more intricate operations or tighter tolerances will increase the machining time, thus raising the overall cost.

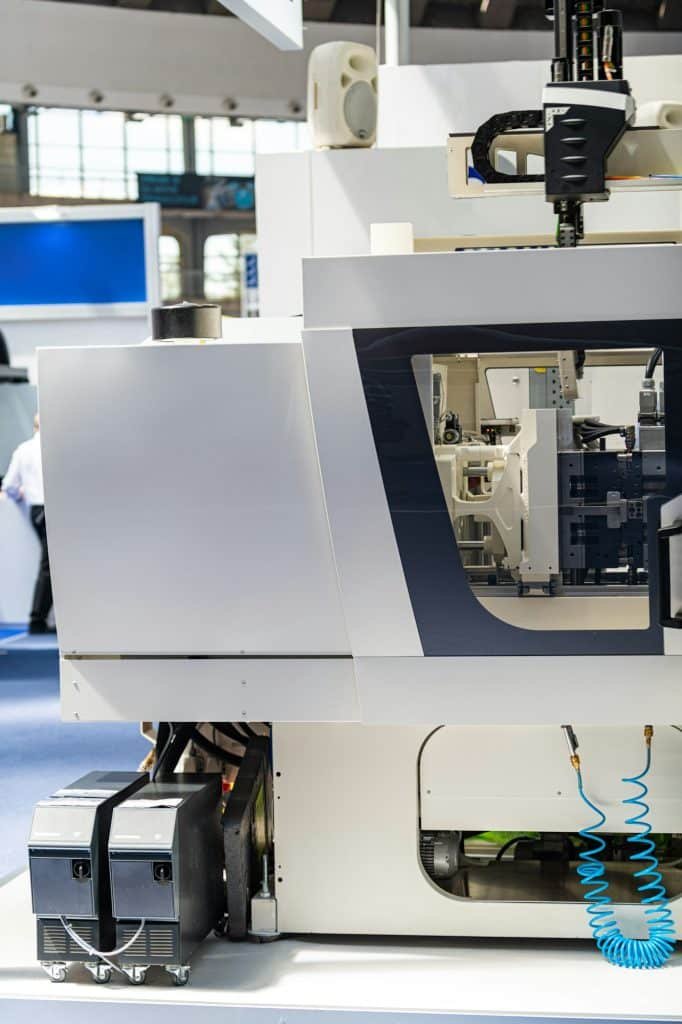

CNC Machine

CNC Machine

3. Labor Costs

Labor costs for CNC machining include the setup time and the time required to program the machine, which can range from $30 to $80 per hour depending on the expertise required and the location. Highly skilled machinists and programmers command higher rates, especially in regions with higher labor costs.

4. Setup Costs

Setup costs are typically a one-time fee associated with preparing the CNC machine for a specific job, which includes programming and tooling. These costs can range from $100 to $500 or more depending on the complexity of the part and the number of operations required.

5. Tooling Costs

CNC machining requires specialized tools like drills, end mills, and taps. While the cost of individual tools might not be high (typically $10 to $100 per tool), the total cost can add up for complex parts that require multiple tools. Some high-end or custom tools can cost several hundred dollars.

Cnc machine in action

CNC Machining Machine

6. Volume of Production

The cost per part decreases with higher volumes due to the amortization of setup costs and machine time over a larger number of parts. For low-volume production (1-100 parts), the cost per part may range from $10 to $100 or more. For high-volume production (1,000 parts or more), the cost per part can drop significantly, sometimes to $1 to $10 per part.

7. Part Complexity and Design

Parts with complex geometries, tight tolerances, or those requiring multiple setups will cost more. Features such as internal cavities, undercuts, and fine details add to the machining time and complexity, thereby increasing the cost.

8. Post-Processing Costs

Additional operations like heat treatment, anodizing, plating, painting, or polishing can add costs ranging from a few cents to several dollars per part, depending on the specific requirements.

9. Inspection and Quality Control

Parts that require extensive quality control or inspection (e.g., aerospace or medical applications) will have additional costs associated with these services. Advanced inspection techniques like the Coordinate Measuring Machine (CMM) can add $50 to $200 per hour.

CNC Machining

Metalworking CNC milling machine.

Overall Cost Estimation

Simple Part: A basic part with a simple design and common material (e.g., aluminum) might cost $10 to $50 for a small production run.

Moderate Complexity Part: Parts with moderate complexity, requiring multiple setups or more expensive materials (e.g., stainless steel), might cost $50 to $200 per part for a small run.

Complex Part: Highly complex parts requiring multiple axes, specialty materials (e.g., titanium), and tight tolerances can cost $200 to $1,000 or more per part, especially for small quantities.