Type-C manufacturers are crucial in the electronic product manufacturing industry, and the efficiency of their warehouse management directly impacts production efficiency and market supply stability. With the widespread adoption of Type-C interfaces across various electronic devices, these manufacturers face new challenges and opportunities in warehouse management. This article delves into the key elements of warehouse management for Type-C manufacturers and explores how optimizing these processes can enhance overall operational efficiency.from HDMI Interface Looking at the development prospects, the future will always bring positive effects. https://www.szxianhe.com/

Accuracy and Timeliness of Materials

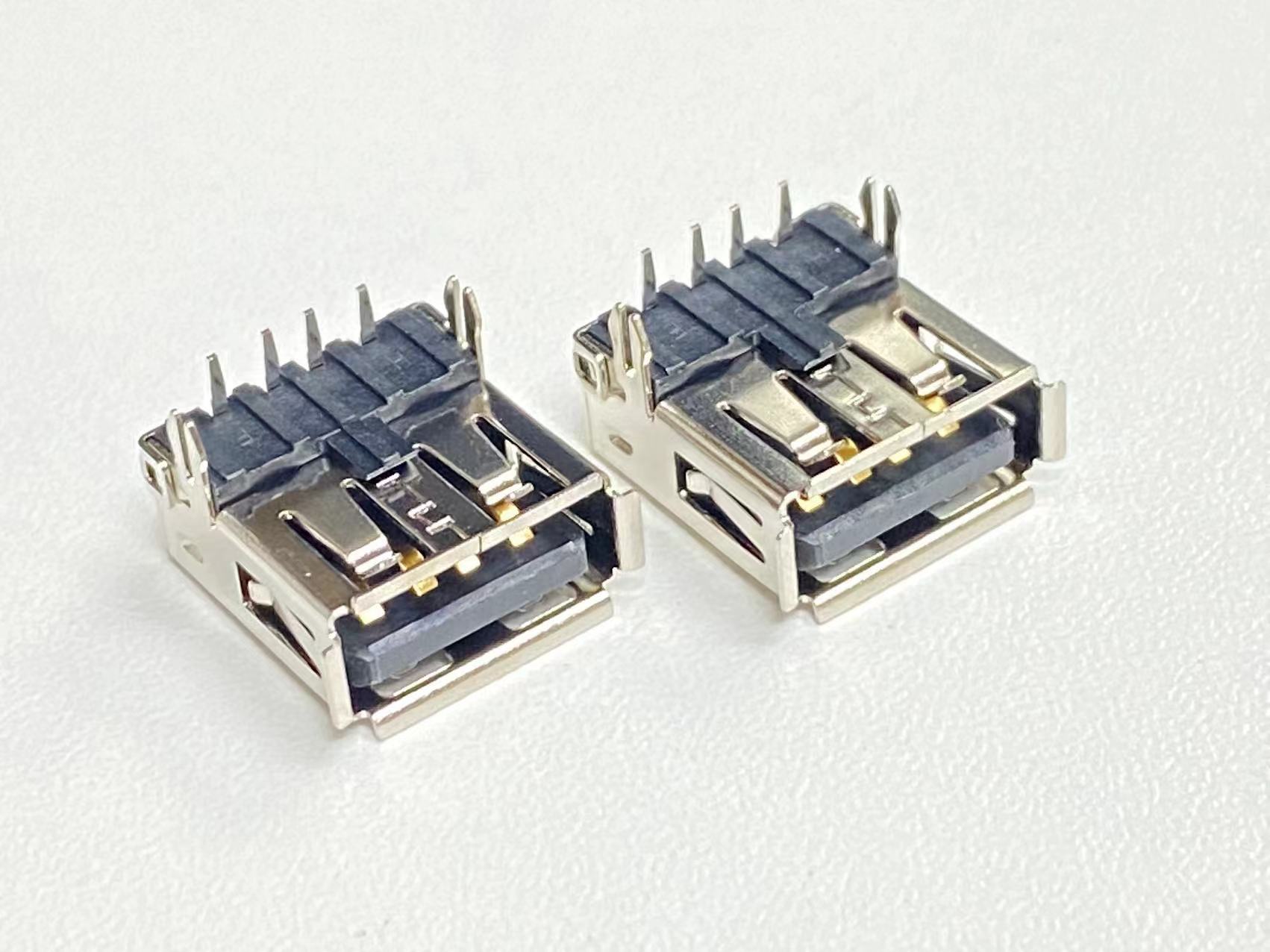

The foremost task in the warehouse management of Type-C manufacturers is ensuring the accuracy and timeliness of materials. The production of Type-C interfaces involves a range of precision components, including connectors, cables, and chips. Accurate record-keeping and timely supply of these materials are essential for maintaining uninterrupted production lines. To achieve this, Type-C manufacturers must implement advanced warehouse management systems, such as ERP (Enterprise Resource Planning) systems. These systems enable real-time monitoring and precise control over material flow, ensuring that every step of the production process operates smoothly and efficiently.

Inventory Optimization

Inventory optimization is another critical aspect of warehouse management for Type-C manufacturers. Excessive inventory levels can lead to increased warehousing costs and capital tie-ups, while insufficient inventory might cause production delays. Type-C manufacturers must strike a balance by optimizing inventory levels through data analysis and predictive models. By leveraging historical sales data and market trend analysis, manufacturers can more accurately forecast future demand, allowing them to adjust inventory strategies accordingly and minimize the risks of overstocking or shortages.

Logistics Efficiency

Efficient logistics are vital for ensuring the quick and safe transportation of materials and finished products, reducing both transportation time and costs. Type-C manufacturers can enhance logistics efficiency by partnering with professional logistics companies, taking advantage of their global networks and specialized services. Additionally, implementing smart logistics technologies, such as automated sorting systems and real-time tracking, can significantly improve the accuracy and responsiveness of logistics operations.